| |

NAPEEC

offers and Supplies the highest quality equipment and

engineering services to meet international standard:

Separators

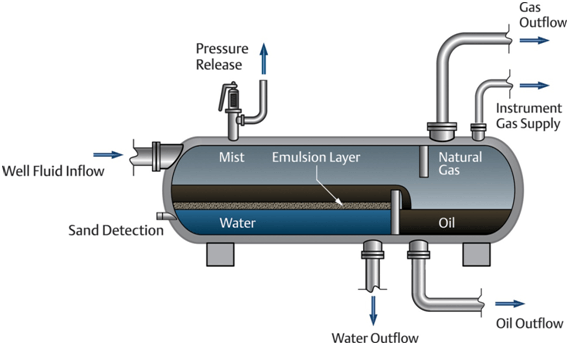

Two and Three Phase Separator Process Description

The purpose of a Two Phase Separator is to divide

the two phase inlet oil-water-gas stream into two

separate phases and in a three phase separator into

three separate phases. In a three phase separator, a

gas phase free of liquid carry-over droplets, an oil

phase free of gas carry-under and water droplets,

and a water phase free of gas carry-under and oil

droplets. Test Separator units usually also provide

metering of the gas, oil and water phases to measure

the production from individual wells.

The effectiveness of gas/liquid and liquid/liquid

separation in Separators is a function of many

factors. Physical properties such as individual

phase density and viscosity are directly related to

separation efficiency, while factors such as wax

content, foaming tendency, surface tension, solids

content and emulsion stability have a major

influence on the design and selection of appropriate

internals. Additional, external, factors may include

the condition of the feed, for example if it arrives

via a control valve or high velocity pipeline there

is a likelihood that the oil and water will have a

very small droplet distribution size and will be

more difficult to separate. Motion effects, such as

are experienced on floating production systems, also

need to be considered.

Various design features and internal devices are

employed to enhance, accelerate or otherwise improve

the efficiency of the separation process from

knowledge of the above factors.

|