| |

|

»

TEG

Gas Dehydration:

TEG Gas

Absorber Tower and TEG Regeneration Unit

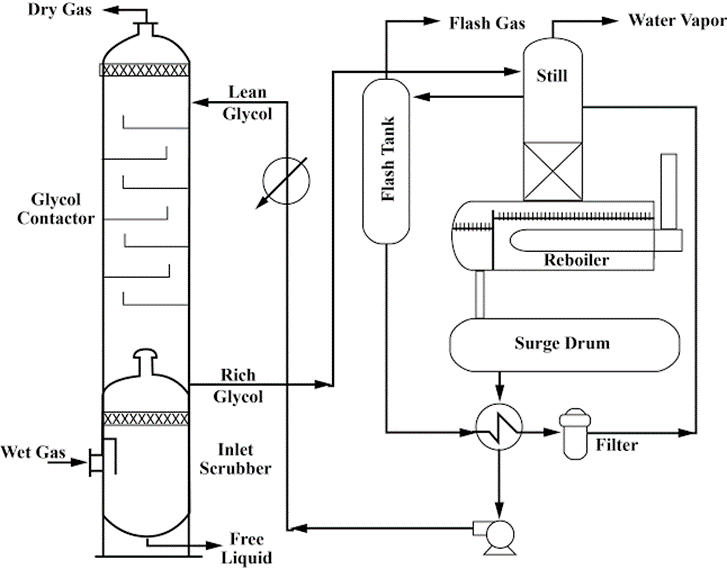

The gas flows through a separator to remove

condensed liquids or any solids that might be in the gas. Some absorbers incorporate the separator in a

bottom section of the vessel, in which case the gas

then flows upward through a chimney tray into the

glycol absorber portion of the vessel. The glycol

contactor or absorber can contain:

- Trays

- Structured packing

If it is a trayed vessel, it will contain several

bubble-cap trays. Lean glycol is pumped into the

upper portion of the contactor, above the top tray

but below the mist eliminator. The trays are flooded

with glycol that flows down from tray to tray in

downcomer sections. The gas rises through the bubble

caps and is dispersed as bubbles through the glycol

on the trays. This provides the intimate contact

between the gas and the glycol. The glycol is highly

hygroscopic, and most of the water vapor in the gas

is absorbed by the glycol. The rich glycol,

containing the absorbed water, is withdrawn from the

contactor near the bottom of the vessel above the

chimney tray through a liquid level control valve

and passes to the regeneration section. The treated

gas leaves the contactor at the top through a mist

eliminator and usually meets the specified water

content.

The rich glycol can be routed through a heat

exchange coil in the top of the reboiler column

called the still. The heat exchange generates some

reflux for the separation of the water from the

glycol in the top of the still and also heats the

rich glycol somewhat. In some installations, the

rich solution passes to a flash tank operating at

about 15 to 50 psig, which allows absorbed

hydrocarbon gas to separate from the glycol. The

glycol then flows into the still through a filter

and a heat exchanger, exchanging heat with the

regenerated glycol. It drops through a packed

section in the still into the glycol reboiler

vessel, where it is heated to the necessary high

regeneration temperature at near atmospheric

pressure. At the high temperature, the glycol loses

its ability to hold water; the water is vaporized

and leaves through the top of the still. The

regenerated glycol flows to the surge tank, from

which it is routed through the lean/rich heat

exchanger to the glycol pump. The pump boosts the

pressure of the lean glycol to the contactor

pressure. Prior to entering the contactor, it

exchanges heat with the dry gas leaving the

contactor or some other heat exchange medium.

Glycol

Regeneration Unit.

|